Ref. No.:POWERPLANT200501

YEAR:2001 -2009

Brand:FOSTER WHEELER, SIEMENS, HONEYWELL ETC.

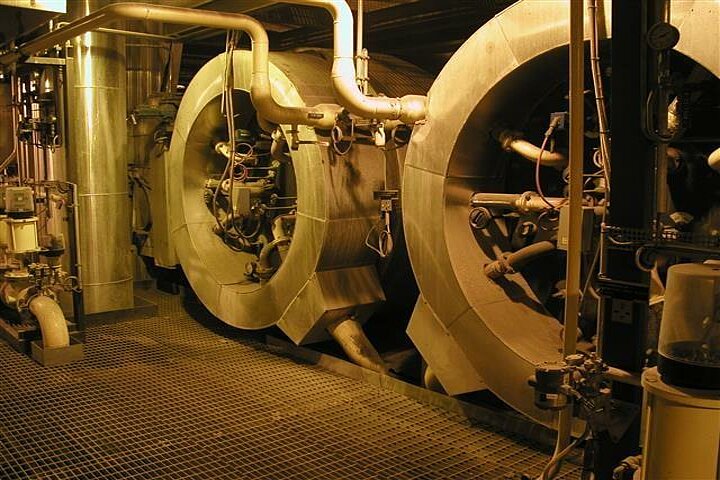

Qty:1 Second-hand power plant including boiler (BFB – boiler bubbling fluidized bed)

Built:2001, 2002, 2006, 2009 Revision

| Description | POWER PLANT INCL. BOILER - BOILER 88 MW - TURBINE 22.5 MW |

| Ref. No. | POWERPLANT200501 |

| Year | 2001 -2009 |

| Brand | FOSTER WHEELER, SIEMENS, HONEYWELL ETC. |

| Qty. 1 Second-hand power plant including boiler (BFB – boiler | bubbling fluidized bed) |

| Mfc. | Foster Wheeler, Siemens, Raumaster, YIT Corporation, Honeywell, |

| Built | 2001, 2002, 2006, 2009 Revision |

| BFB Boiler – 88 MW Steam turbine – 22.5 MW | |

| Main Steam Cycle | |

| BFB boiler K7 | |

| – Some parts removed and storaged indoor at the paper mill area | |

| – Boiler is made electrically safe (cables cut) | |

– Dry conservation ongoing since 2014 (tubes filled with nitrogen, dry air circulation) | |

| – Steam Turbine VP4 (in storage) | |

| Generator (in storage) | |

| Power Plant – Function | |

Primary function is to produce steam for the Paper Mill reliable and economically | |

| Secondary functions | |

| Burning of the Paper Mills (PM) waste wood | |

| Incineration of sludge from the PM | WWTP |

Production of flue gas to the PCC (precipitated calcium carbonate) plant | |

| Electricity production | |

| District heating production | |

| Scope of supply - main machinery and key components | |

Feed water pumps and motors 2 pc High-pressure preheater, feed water heater | |

| Feed water valves Injection water system | |

| Steam drum Combustion chamber | |

| Fuel drop funnel 4 pc Start-up burners 2 pc | |

| Load burners 2 pc Waste oil burner, waste oil tank | |

| Natural gas filters Economiser | |

| Air-preheater Super heater | |

| Exhaust system Main steam valve | |

| Safety valves Dust removing system | |

| Bed material system, bed sand silo Bed sand preparing | |

| Bed lime system, lime silo Furnace ash system | |

| Fly ash system, fly ash silo and screws Primary air blower | |

| Secondary air blower Twist grip blower | |

| Bag filter Flue gas blowers 2 pc | |

| Flue gas scrubbers, lye system, scrubbers sludge system | |

| Safety locking system Nitrogen preservation system | |

| Chemicals dosage and chemical pumps Sample system | |

| Chimney | |

| Technical Data | |

| BFB-boiler K 7 | |

| Mfc. | Foster Wheeler Oy Commissioning |

| Heat Output | 88 MWth Steam parameters |

| Feed water temp. | 135-190°C Flue Gas Exit temp. |

| Boiler Efficiency | 88.5% SO2 Emissions |

| NOx | < 425 mg/Nm3 PM |

| Operation time | 88 000 hour Latest revision in 2009 (air preheater) |

| Maintenance revision annually Operation manual | |

| Main Fuels Bark, saw dust, wood chips and waste wood | |

| Sulphur <0,05% Moisture 30-65% LHV 3.7-6.9 MJ/kg | |

| Peat Sulphur 0.25% Moisture 40-58% LHV 6.3-11.3 MJ/kg | |

| Sludge from WWTP | |

Sulphur 0.2 – 1.7% Moisture 65-75% LHV >0.5 MJ/kg max. 7% of fuel power | |

| BFB Boiler K7 - Flue Gas Treatment | |

| Bag Filter Mfc. | Alstom 4 chambers |

| 376 bags 7 m long | |

| DAS (Dry Absorption System) Pre-coating with Ca(OH)2 | |

| Max. operating temperature 200 °C | |

| Flue Gas Scrubber Mfc. | Ehox Tuote |

| 2 scrubbers - 1 in operation 27 Nm3/s, 170°C in | |

20 Nm3/s, 43°C out Heat Recovery 18 MW at low temperature, 60°C | |

| Solid fuel system for K7 (NOT ALL AVAILABLE BY THE OWNER) | |

| Mfc. | Raumaster Built |

| Maintenance revision annually Operation manual | |

| Excluded | Not available by owner |

| Bar conveyor Crusher Fuel batching screw, fuel-receiving pocket | |

| Scraper conveyor to screen hall Screen system | |

| Scraper conveyor to silos and scraper conveyor on the silos | |

| Peat silo, fuel-batching screw (batching screw not existing) | |

| Bio fuel silo, fuel batching screw (batching screw not existing) | |

| Fuel line from silos | |

| Included | |

| Fuel line 1 from SFS to the boiler Fuel line 2 from SFS to the boiler | |

Back-up fuel pocket and fuel batching screw Fuel batching screw at power plant | |

| Robbery fuel batching screw Batching bin 2x50 m3 | |

Scraper conveyor at the boiler 2 pc Fuel batching pockets & fuel batching screw | |

| Fuel feeder 4 pc Fuel sample crusher | |

| Extinguishing steam system | |

| Sludge system for K7 | |

| Built | 2002 |

| Excluded | Not available by owner |

| Compressor Sludge pneumatic press | |

| Sludge pipe cleaning system Blowpipe to the power plant | |

| Included | |

| Cyclone Sludge silo and batching screw | |

| Automation and electrical equipment, spare parts for K7 | |

| Included | |

| Mfc. | Honeywell Type |

| Field instruments (as it is on the field) Motors | |

| Frequency changers Automatic valves etc. (as it is on the field) | |

Auxiliary devices (as it is on the field) All available existing specific spare parts | |

| Excluded | |

| Radioactive sources | |

| Steam Turbine/Generator VP4 (removed & in storage) | |

| Turbine | |

| Mfc. | Siemens Type |

| Power | 22.5 MW Reactive power |

| In operation since 2009 until 2012 Operation time | 24 000 h |

| Revolution | 8274 RPM Inlet pressure |

| Inlet temp. | 525 °C Inlet flow |

| Tap-off pressure | 3.7 – 24.1 bar Tap-off temp. |

| Tap-off flow | 7.9 – 33.5 kg/sec. Outlet pressure |

| Outlet temp. | 144 – 205 °C Outlet flow |

| Operation manual | |

| Generator | |

| Mfc. | Siemens Teho Generation AG Type |

| Nominal output | 28.5 MVA Power |

| Voltage | 6.3 kV (+5/-10%) Rated current |

| Frequency | 50 Hz In operation since 2009 until 2012 |

| Operation time | 24 000 h Operation manual |

| Included | |

| Turbine Gearbox Turning gear Generator | |

| Generator cooler Oil system Siemens automation system | |

| Automation and electrical equipment (as it is on the field) | |

| Motors Frequency changers Valves | |

Auxiliary devices (as it is on the field) All available existing specific spare parts | |

| Water treatment system at the power plant | |

| Mfc. | YIT Built |

| Raw water purification and desalination Operation manual | |

| Raw water purification | |

| Max capacity | 146 m3/h Capacity |

| Included | |

| Pumps and compressors Tanks | |

| Flock-filtering system 2 pc Preheater of raw water | |

| Automation and electrical equipment (as it is on the field) | |

| Motors Frequency changers Valves | |

Auxiliary devices (as it is on the field) All available existing specific spare parts | |

| Desalination | |

| Net capacity | 2 x 72 m3/h |

| Included | |

| Cation exchangers 2 pc A1/A2 exchangers 2 pc | |

| MB exchangers 2 pc Tanks | |

| Pumps Heat exchanger | dilution water of lye |

| Automation and electrical equipment (as it is on the field) | |

| Valves Motors Frequency changers | |

Auxiliary devices (as it is on the field) All available existing specific spare parts | |

| Steam, condensate and feed water system | |

| Included | |

| Feed water tank Condensation tank | |

Purification of condensation, precoat-system Condensed steam pumps | |

| Steam tanks Steam condenser | |

| Reduction valves Steam-pressure accumulator | |

| Cooling water system | |

| Automation and electrical equipment (as it is on the field) | |

| Valves Motors Frequency changers | |

| Common electrical equipment | |

| Process central | |

| Distribution transformers | |

| 1 pc 400 V 1.25 MVA 2 pc 690 V 3.15 MVA |