Metal production

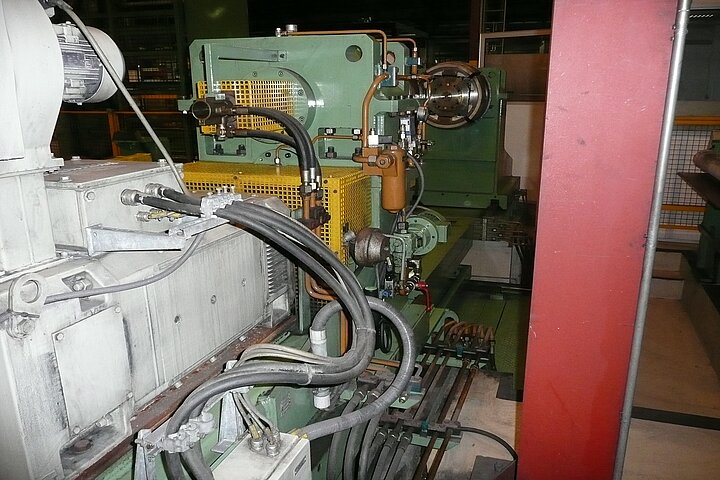

SLITTING LINE - BRS1200

Ref. No.:SLITTER121101

YEAR:1993 / 2004

Brand:TILGERT

Qty:1 Second-hand Slitting Line

Specification

| Description | SLITTING LINE - BRS1200 |

| Ref. No. | SLITTER121101 |

| Year | 1993 OVERH |

| Brand | TILGERT |

| Qty. 1 Second-hand slitting line | |

| Mfc. | Tilgert Type |

| Revamped | complete new electrical system, new end coiler & loading system – 2004 |

| Scope of supply | |

| Scrap coiler Coil preparation station Coil placement 1 + 2 | |

| Coil lifting car Unwinder Grease lubrication station | |

| Strip underpass Changing car Knife cassettes | |

| Coiler with strip guide Clamping shafts Trimming scrap disposal | |

| Coil discharge Safety devices Hydraulic system | |

| Electrical switchgear | |

| 2.1 Technical data | |

| 2.1.1 Material data | |

| Materials | aluminium and aluminium alloys (series AA 3000 and AA 8000) |

| Tensile strength Rm | 100 to 250 N/mm² Strip thickness |

| Strip width | 800 to 1,250 mm (single strips) |

| 2.1.2 Coil dimensions on unwinder | |

| Coil inside dia. | coils are wound centrally on cylindrical steel spools (site spools) |

| Coil outside dia. | max. 2,100 mm Winding ratio |

| Coil weight, max. | 10,700 kg (without steel spool) |

| Coils are wound firmly with straight edges. | |

| 2.1.3 Site spool for unwinder | |

| Spool inside dia. | 598 mm Spool outside dia. |

| Length | 1,830 mm Surface DIN ISO 1302 |

| Weight | 880 kg |

| 2.1.4 Coil dimensions on coiler | |

| Coil inside dia. | The strips are wound on paper board spools. |

| Coil outside dia. | max. 800 mm Winding ratio |

| Coil weight, max. - Winder 1 | 800 kg - Winder 2 |

| 2.1.5 Paperboard spools for coiler | |

| Spool inside dia. | 150 mm +/-0.5 mm Spool outside dia. |

| Length | corresponding to strip width |

| 2.1.6 System data | |

| Pull-in speed | 15 m/min |

| System speed - without grease lubrication | 0 to 500 m/min |

| - with grease lubrication | 0 to 450 m/min |

| Strip tension - Unwinder | max. 6,000 N - Coiler, winder 1 |

| - Coiler, winder 2 | max. 1,800 N with 1 motor |

| max. 3,600 N with 2 motors | |

| Direction of strip travel | from right to left |

| (operating side looking in direction of strip travel, left) | |

| Baseline | strip always runs on system centre |

| Cutting method | circular knife cut with spring-loaded single knives |

| Knife axle dia. - Bottom axle | dia. 100 f7 - Bottom knife |

| - Top axle | dia. 60 f7 |

| - Top knife | max. dia. 105 mm / min. dia. 95 mm |

| - Thrust ring | dia. 85 / dia. 70 / dia. 60 |

| Cutting capacity | max. 20 strips (10 per coiling axle) |

| Strip width - on 2 coiling axles | 20 to 600 mm - on 1 coiling axle |

| Cutting tolerance | ½ DIN 1784 p. 2 |

| 2.1.7 Energy data | |

| Operating voltage | 400 V, 50 Hz |

| Control voltage - Electrical functionality | 230 Vac, 50 Hz |

| - Hydraulic functionality | 24 Vdc - Pneumatic functionality |

| Operating pressure - Hydraulic functionality | 120 bar |

| - Pneumatic functionality (general) | 6 bar (provided by customer) |

| - Pneumatic functionality (coiling axles) | 10 bar |

| 2.2 Description of machines | |

| 2.2.1 Scrap coiler Carrying capacity | 750 kg Coiler head dia. |

| Useful width | 1,650 mm Coil outside dia. |

| Winding speed | max. 30 m/min |

| Winding drive | 4 kW, 3 ph., frequency converter |

| Coil takeup prism Useful lift | 190 mm Lift drive |

| 2.2.2 Coil preparation station Carrying capacity | 12,000 kg |

| Holding capacity | 1 coil, centrally wound on site spool Bearing pulley dia. |

| Bale width | 40 mm Number of bearing pulleys |

| Drive | 3 kW, 3 ph., frequency converter Useful width |

| 2.2.3 Coil placement rack 1+2 | |

| Carrying capacity | 2 x 12,000 kg |

| Holding capacity | 2 coils, centrally wound on site spool Useful width |

| 2.2.4 Coil lifting car | |

| Coil receptacle Carrying capacity | 12,000 kg |

| Holding capacity | 1 coil, centrally wound on site spool |

| Useful width | 1,600 mm Useful lift |

| Spool receptacle Carrying capacity | 1,200 kg Holding capacity |

| Useful lift | 865 mm Lift drive |

| Chassis Travel | 8.0 m |

| Drive | 2.2 kW, three-phase, frequency converter Speed |

| 2.2.5 Unwinder Carrying capacity | 12,000 kg Coiler head rated dia. |

| Coiler head spread | 472.5 to 610 mm Useful width |

| Drive | 0 – 64.5 – 64.5 kW, 0 – 650 – 2000 min-1 Winding gear |

| Gear unit | i = 8.03 Unwinding |

| Coiler centre above shop floor | 1,350 mm |

| Lateral adjustment | #ОШИБКА! |

| 2.2.6 Grease lubrication station | |

| Notched roll dia. | 200 mm Pressure roll dia. |

| Guide roller dia. | 120 mm Bale width |

| Notched roll drive | 3 kW, DC |

| 2.2.7 Strip underpass | |

| Guide roller dia. | 120 mm Bale width |

| Guide roller number | 2 |

| 2.2.8 Changing car | |

| Carrying capacity | 2 knife cassettes Travel |

| 2.2.9 Knife cassettes Number | 3 |

| Knife axle dia. | - Bottom axle |

| - Top axle | dia. 60 f7 - Top knife |

| Knife axle width | 1,300 mm Drive, bottom knife axle |

| 2.2.10 Coiler with strip guide | |

| Entry guide Guide roller dia. | 120 mm Bale width |

| Guide roller number | 2 Adjustment drive |

| Adjustment range | 80 mm |

| Delivery guide | |

| Guide roller dia. | 120 mm, hard chrome plated 140 mm, rubber coated |

| Contact roller dia. | 200 mm, hard chrome plated |

| Bale width | 1,270 mm Guide roller number |

| Contact roller number | 2 |

| Winder 1 Carrying capacity | max. 800 kg |

| Drive | 0 – 21.5 – 25 kW 0 – 600 – 2000 min-1 |

| Direction of turn | 1 winding direction Winding gear |

| Winder 2 Carrying capacity | max. 1,300 kg |

| Drive | 0 – 21.5 – 25 kW, 2 drives 0 – 600 – 2000 min-1 |

| Direction of turn | 2 winding directions |

| Winding gear | - 1 drive |

| 2.2.11 Clamping shafts | |

| Outside dia. | 148 mm Spread |

| Overall length | 1,400 mm Body length |

| Core diameter | 150 mm Core composition |

| Spool length, max. | 1,200 mm Strip width, max. |

| Coil dia. | max. 800 mm Carrying capacity |

| Winding gear | max. 3,600 N Torque |

| 2.2.12 Trimming scrap disposal | |

| Strip thickness | 0.025 to 0.250 mm Strip width, max. |

| Number of strips | 2, simple System speed |

| Precutter, type FS 300 Drive | 2 x 7.5 kW, 3 ph., |

| Knife | carbide metal knife (shortened, with special polish) |

| Transport ventilator, type CH-T Air volume/rate | 4,000 m³/h |

| Overall press | 700 daPa Ventilator speed |

| Drive | 2 x 22 kW, 3 ph. Speed |

| 2.2.13 Coil discharge | |

| Carrying capacity | 2 x 1,500 kg Useful lift |

| Lift drive | 2 x 4 kW, 3ph., frequency converter |

| Travel | 5,900 mm Coil placement |

| Drive | 1.5 kW, three-phase, frequency converter |

| 2.2.14 Hydraulic system | |

| Drive power | 11 kW Delivery rate |

| Operating pressure | 120 bar |

| Pump | vane pump with pressure regulator, made by Rexroth |

| Tank volume | 250 l |

| Pressure fluid | hydraulic oil HLP46 to DIN 51 524 part 2 |

| Viscosity | 46 mm²/s at 40°C Operating temperature |

| Emergency cutout | >70°C |

| Purity | < 10 µm (NAS 1638 class 7 to 9, β10 > 75) |

| Valves | made by Rexroth with connector 24 Vdc |

| Pipes | Ermeto, heavy-duty range |

| Joints | welded nipple with O-ring seal |

| Attachment | Stauff clamps, heavy-duty range |