Metal production

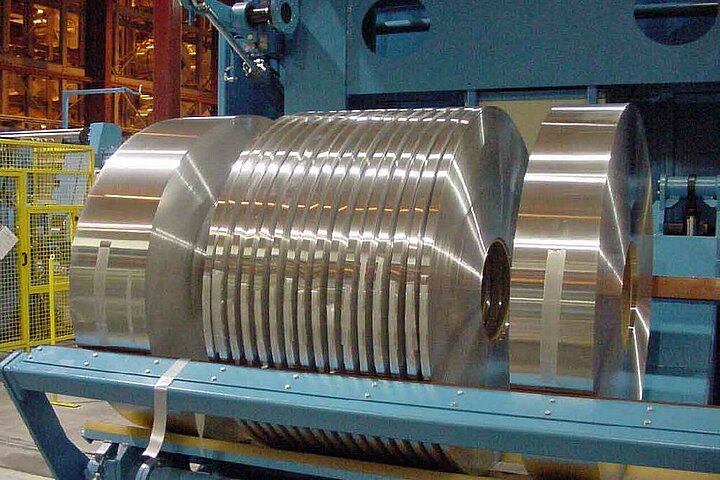

SLITTER - WIDTH: 635-1753 MM - THICKNESS: 0.05-0.38 MM - SLITTING WIDTH: 15.8-1169 MM

Ref. No.:SLITTER190601

YEAR:2001REINTALL

Brand:KAMPF

Qty:1 Second-hand slitting line

Specification

| Description | SLITTER - WIDTH: 635-1753 MM - THICKNESS: 0.05-0.38 MM - SLITTING WIDTH: 15.8-1169 MM |

| Ref. No. | SLITTER190601 |

| Year | 2001 & RE-INSTALLED |

| Brand | KAMPF |

| Qty. 1 Second-hand slitting line | |

| Mfc. | Kampf Built |

| Material Processed | Al. Alloys 1145, 1100, 3003, 7072 and 8111 Temper |

| Strip Width | 635 - 1753 mm (25" - 69") Thickness |

| Slitting Width | 15.8 mm - 1169 mm (0.6" - 46") Max. 40 Cuts Plus Edge Trim |

| According to Kampf, this Line will run Can Lid Stock | 0.93 mm (0.037") and |

| "O Temper" Dead Soft Aluminum at 2.06 mm (0.081") with Knife Modifications. | |

| Line Speed Max | 800 m/min. (2600 Ft/min.) depending on material type, thickness, etc. |

| Consisting of the Following | |

| Unwind Reels | Coil OD |

| Spool Size | I.D./O.D./Length |

325 x 406 x 1676 mm (12.812" x 16" x 66") – 304.8 x 406 x 698.5 mm (12"x16"x27.50") | |

| Unwind and Coil Stands to be designed to accept future | |

| Spool length of 1930.4 mm (76") | |

| Rewind Reels | |

| Slitting Width | 15.8 mm - 1169 mm (0.6" - 46") Max. 40 Cuts Plus Edge Trim |

| Reels Diameter O.D. Max. | 1829 mm (72") O.D. Min. |

| Depending on Material Type, Thickness, etc. | |

| Spool/Core I.D | 152, 254, 304, 406 mm (6, 10, 12, 16") Fiber Cores (Cardboard) |

| Slitting System | Scissors Cut |

| Edge Trim Min./Max. | 12.7 - 50.8 mm Per Side (0.5" - 2.0" Per Side) |

| Slit Width Tolerance | #ОШИБКА! |

| Acceleration/Deceleration | Vo - V Max. in approx. 80 S |

| Instantaneous Stop | V Max - Vo in approx. 40 S |

| Emergency Stop | V Max - Vo in approx. 10 S |

| Winding Tension/Unwind | Max. 12.650 N |

| Winding Tension/Rewind 1 | 318 - 6328 N/25% Taper Tension at Outer Diameter |

| Winding Tension/Rewind 2 | 318 - 8438 N/25% Taper Tension at Outer Diameter |

| Elongation Unit (Stretcher) Capability | 1.5 - 3.0% with a Target of 2.0% |

| Machine Design | Drive side on the right, as seen in material running direction. |

| Voltage | 480 V + 10%-20% AC-3 Ph. - 60 Hz +/- 2% Control Voltage |

| Total Supply Power Value | approx. 700 kVA |

| Air Continuous Pressure | >/- 5,5 Bar >/- 77 Psi Consumption approx. |

| Water Flow | 1.5 M3/H 53 Cu Ft/H |

| Main Machine | |

| Drive Side on the right Unwind with Stepped Expanding Heads Stretch Stand | |

Two Slitting Cassettes Pusher Plates on Rewinds Drives, Motors and Sps from Siemens | |

| Siemens Programming Unit with Modem and Programs | |

| Winding Shafts | 2 Rewind Shafts – 152 mm (6") 2 Rewind Shafts – 254 mm (10") |

| 2 Rewind Shafts – 305 mm (12") 2 Rewind Shafts – 406 mm (16") | |

| Handling for Unwind Side including | |

| Coil Car with Fixed Saddle Core Roller Table with Core Deposit | |

Two Coil Deposit Stand Non-Driven (Spools 1676, 1800 & 1930 mm (66", 72", 76")) | |

| Empty Spool Roller Table with Spool Deposit | |

| Handling for Rewind Side including | |

| 2 Finish Roll Transport Cars Vacuum Hose and Maintenance Platform | |

| Edge Trim Suction, Chopper, Transport and Air-Separator, Diverter Gate, |