Ref. No.:PAINTINGPLANTVERT211101

YEAR:2007

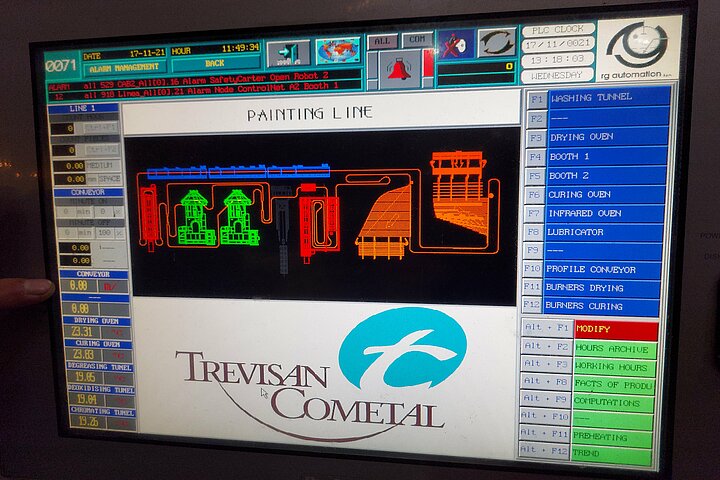

Brand:TREVISAN COMETAL

Qty:1 Second-hand Vertical Powder Coating Line for Aluminium Profiles

Qty. 1 Second-hand Vertical Powder Coating Line for Aluminium Profiles

Mfc.: Trevisan Cometal Built: 2007 Type: IV/7.00

Profile dimensions: 7000 x 150 x 200 mm - H x W x D

Weight of profiles: 25 kg/each max. Total weight on the chain: 10,000 kg

Weight distributed linearly for only 1 meter: 50 kg/m of chain

Conveyor speed: 1.5 m/min. Temp. in the polymerisation furnace: 170÷195 °C

Rated hanging pitch along the chain: 66/100/133/200 mm

Scope of supply:

Pre-treatment tunnel Drying oven Painting system Cleaning system

Infrared oven Polymerisation oven Descending chain conveyor

Transport system

Supply Sources

Electricity: 380 V, 3 ph., 50 Hz

Thermal energy Natural gas equipment pressure: 60÷200 (2)mbar

Hot water 95 °C

Compressed air Equipment pressure: 7.0 (3) bar

Steam max. level: 1.3 g/Nm3 Oil max. level: 0.01 ppm

Water system Pressure: 3±0.2 bar

Powder Characteristic of powder to use: LEL 40 g/Nm³ (LEL: lower Explosion Level)

Power Installed

| Machine | Electric power - kW | Thermal power – kcal/h |

| Tunnel | 75 | (600,000) |

| Principal Booth | 55 | - |

| Secondary Booth | 55 | - |

Drying oven + Transfer units | 5 | 280,000 |

| Infra Red Oven | 43 | 220,000 |

Curing oven + Conveyor | 35 | 560,000 |

| Cleaning unit | 9 | - |

| Infrared hook cleaning machine | 35 | - |

| Descending chain & hook lubricator | 3 | - |

| Demi water unit | 5 | - |

| Boiler | 8 | 700,000 |

Total | 328 | 1,760,000 |

Process Cycle

Time refers to a conveyor speed of 1.5 m/min:

| Operation | Time at 1.5 m/min | Temperature - °C |

| Work piece loading | - | - |

| Alkaline Degreasing | 1’45’’ | 50 |

| I Rinse: recirculated town water | 30’’ | Room |

| II Rinse: fresh town water (~2 m³/h) | 30’’ | Room |

| Acid Deoxidating | 2’20’’ | 40 |

| I Rinse: recirculating town water | 30’’ | Room |

| II Recirculation demi rinse: fresh demi water (~4 m³/h) | 30’’ | Room |

| Chromating (refilled with demi water) | 1’10’’ | 30 |

| Pre-rinse fresh town water (~1 m³/h) | 30’’ | Room |

| Recirculation rinse | 30’’ | Room |

Pure demi rinse (fresh demin. water 12 m³/h) | 20’’ | Room |

| Drying | 12'' | 60÷80 (air temp.) |

| Powder coating | - | - |

| Infrared oven | ~1’ | - |

| Curing | 20’ | 170÷195 (air temp.) |

| Work piece unloading | - | - |

Pre-treatment tunnel

Operating data

Termic power required: 600,000 kcal/h Electric power installed: 75 kW

Baths Heating System: hot water at 95°C Town water consumption: 6 m3/h Demi water consumption: 12 m3/h

Specification

| Stage No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Operation | Alkaline degreasing | I Rinse town water | II Rinse town water | Acid deoxidisation | I Rinse town water | II Rinse town water | Chromating | Pre-rinse town water | Recirculation on demineralised water rinse | Clean on demineralised water rinse |

| Time at 1.5 m/min | 1’45’’ | 30” | 30” | 2’20” | 30” | 30” | 1’10” | 30” | 30” | 30” |

| Temperature °C | 50 | Room | Room | 20 | Room | Room | 30 | Room | Room | Room |

| Pump power kW | 7.5 | 2.2 | 2.2 | 11 | 2.2 | 2.2 | 5.5 | 2.2 | 2.2 | Demi pump |

| Heating power kcal/h | 300,000 | - | - | 150,000 | - | - | 150,000 | - | - | - |

Ramps feeding pumps table

Stage | No. | Brand | Type | Flow rate m³/h | Power kW |

| 1 | 1 | Travaini | TCHM 65-125/1-C/A3 | 66 | 7.5 |

| 2 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 2.2 |

| 3 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 2.2 |

| 4 | 1 | Travaini | TCHM 65-125/1-C/A3 | 88 | 11 |

| 5 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 2.2 |

| 6 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 2.2 |

| 7 | 1 | Travaini | TCHM 50-125/1-C/A3 | 44 | 5.5 |

| 8 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 2.2 |

| 9 | 1 | Travaini | TCHM 40-125/1-C/A3 | 22 | 5.5 |

| 10 | 1 | Demi Unit | TCHM 50-125/1-C/A3 | 12 | - |

Ventilating Plant

The tunnel is equipped with a centralized suction system preventing the vapours and smog produced inside the tunnel from escaping through the mouths meant for incoming/outgoing pieces.

The plant is composed of a system of intakes, properly disposed along the tunnel, of a PVC manifold, and of a centrifugal electric suction device.

Centrifugal electric suction device

Brand: PLASTIFER SNC Type: VSB 70 PP Flow: 16.000 m³/h Pressure: 1310Pa Electric Motor power: 15 kW, 950 RPM

Drying Oven - Installed Devices

| Item | Qty. | Brand | Type | Power |

| Temperature probe | 1 | RG Aut - SIDIS | PT100, 8x400mm, conv 4.20mA | - |

| Phyrostat | 1 | RG Aut- SIDIS | TC J, 8x400mm 1/2DIN | - |

| Recirculating Fan | 3 | General Fans SrL | F6 700/30°/fa 19x40 op | - |

| Fan motor | 3 | Carpanelli Motori | M90L6 | 1.1 kW, 6 Pol |

| Burner | 1 | Weishaupt | G 1/1 – E esec.ZD | 60÷335 kW |

Booth - Installed Devices

| Item | Qty. | Brand | Type | Characteristics |

| Reciprocator motor | 1 | Carpanelli Motori Elettrici S.p.A. | MA100a4 | 2.2 kW, 230/400 V, 50 Hz, autofrenante 4 poli |

| Reciprocator gear box | 1 | Varvel | FRS 130 S | R1:20 IEC100 B5 (28 250), AC48 CS cuscinetti conici: 32015 XA" |

| Rolling spool motors | 2 | Carpanelli Motori Elettrici S.p.A. | M80a4 | 0.56 kW, 230/400 V, 50 Hz, 4 poli |

| Rolling spool gear box | 2 | Varvel | FRT60 B3 | R1:49 IEC 80 B5 (19 200) AC25 |

| Extraction fan | 1 | Ind. CBI S.p.A | KB 36 M6 | 22000 m3/h, 550mmH20; 45 kW (SSW), 1470 RPM |

Cleaning Unit - Installed Devices

| Item | Qty. | Brand | Type | Characteristics |

| Aspiration fan | 1 | EFFEPIZETA S.r.l. | SLC K 11 MS | 9.2 kW, 400 V, 50 Hz, 915 m3/h, 225 mbar |

| Safety valve | 1 | EFFEPIZETA S.r.l. | VRL 8 | 9.2 kW, 400 V, 50 Hz, 915 m3/h, 225 mbar |

IR Oven - Installed Devices

| Item | Qty. | Brand | Type | Characteristics |

| Radiating panels | 60 | Aricat | V2005 | Natural Gas, 415x510mm, R: 600 W, 230 V, 50 Hz, Thermostat UL |

Pre-Oven & Oven - Installed Devices

| Item | Qty. | Brand | Type | Characteristics |

| Temp. probe | 3 | RG Aut - SIDIS | PT100 | 8x400 mm, conv 4.20 mA |

| Phyrostat | 1 | RG Aut - SIDIS | TC J | 8x400mm 1/2DIN |

| Extraction fan | 1 | Ind. CBI S.p.A. | LB250 | 1776 m3/h, 46,6mm H20; 0.55 kW, 50 Hz, 2645 rpm |

| Burner | 2 | Weishaupt | G 1/1 – E esec.ZD | 60÷335 kW |

Transport System - Installed Devices

| Item | Qty. | Brand | Type | Characteristics |

| Driving unit | 3 | CARPANELLI S.p.A. | M80 a4 | 0.56 kW, 2 poles, 230/400 V, 50 Hz, Temp.: 130°C, Servo fans: 230 V, 50 Hz |