Ref. No.:FOILROLLMILLPL160901

YEAR:2001

Brand:WORLD

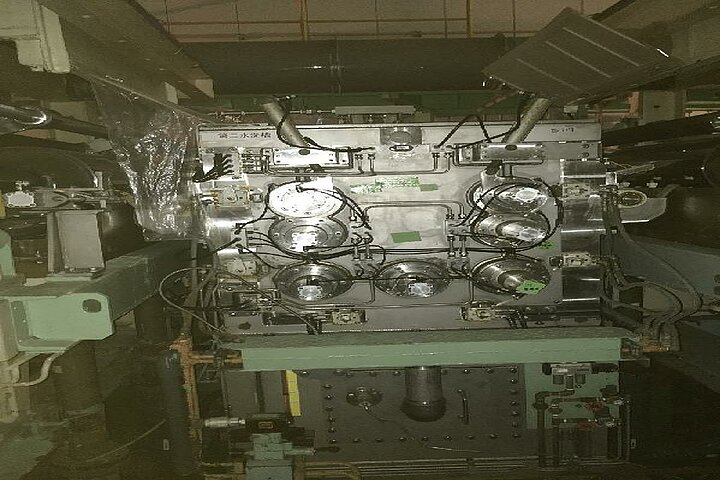

Qty:1 Second-hand Foil Rolling Mill Plant

| Description | FOIL ROLLING MILL PLANT - 6-HI, NON REVSING, 400-700 MM, THICKNESS EXIT: 5 -100 MICRONS |

| Ref. No. | FOILROLLMILLPL160901 |

| Year | 2001 |

| Brand | WORLD |

| Qty. 1 Second-hand foil rolling mill | |

| Mfc. | World Co. (Japan) Type |

| Application | Copper foil Width |

| Thickness Entry | 100 – 200 microns Exit |

| Speed | 0-400/800 m/min. Thickness X-Ray unit AGC system Variable Crown Control |

| Hydraulic servo equipment Main motor power | 200 kW DC |

| Slitter line Mfc. | IHI Width |

| Degreasing line Mfc. | World Co. Strip width |

| Treatment line Mfc. | Kawasaki Built |

| Technical specification | |

| 1.Copper foil rolling mill Mfc. | World(Japan) Built |

| Type | 6-Hi, non reversing mill Material |

| Hydraulic servo equipment Speed | 0-400/800 m/min |

| Width | 400-700mm Coil outer diameter |

| Coil weight | Max. 5 ton Main motor |

| Thickness | Entry |

| Thickness X-Ray unit AGC System Threading speed | 10 m/min. |

| Coil max. dia. | 1100 mm Variable Crown Control |

| Spool sizes | ID 298 OD 330 mm L=900 mm Qty. 10 sets |

| Electric voltage | 440 V, 3 ph., 50 Hz Total power |

| Rolling force | 160 tons hydraulic servo cylinder push up type |

| Main parts of the rolling mill | |

Mechanical unit Mill housing 1 lot Universal joint 2 sets Pinion stand 1 unit Pay off reel 1 unit Winder 1 unit Payoff off reel gear box 1 unit Winder gear box 1unit Payoff reel coil car 1 unit Winder coil car 1 unit Roll force hydraulic unit 1 lot Normal hydraulic unit 1 lot | |

VC (Variable Crown Control) roll hydraulic unit 1 lot Lubrication circulation unit 1 lot Roll coolant tank 1 lot Pump units (roll coolant) 1 lot | |

Temperature control unit (roll coolant) 1lot Filter unit (roll coolant) 1 lot Oil mist system 1 lot Micronlube unit (for guide roll) 1 lot | |

| Electric control system 1 lot Backup roll 1lot Work roll 1 lot | |

| Electric system Mill motor DC 200 kW, 440 V Pay off reel motor DC 35 kW, 440 V | |

| Winder motor DC 35 kW, 440 V Roll force hydraulic unit AC 7.5 kW, 200 V | |

| Normal hydraulic unit AC 11 kW, 200 V, AC 505 kW, 200 V | |

| VC (Variable Crown Control) roll hydraulic unit AC 7.5 kW, 200 V | |

| Lubrication circulation unit AC 1.5 kW, 200 V | |

| Pump unit (coolant) AC 15 kW, 200 V (2 units), AC 7.5 kW, 200 kW | |

| Oil mist AC 0.75 kW, 200 V | |

| 2. Slitter line Mfc. | IHI(Japan) Built |

| Width | 150-700 mm Thickness |

| Foil tension | 45 kg/mm², 450 N/mm² |

| Pay off reel spool dia. | ID 150 mm OD 200 mm & ID 290 mm OD 330 mm |

| Pay off reel coil width | 900 mm Pay off reel coil dia. |

| Pay off reel coil weight | 1.5 T Pay off reel tension |

| Winding spool | ID 76.2 mm OD 110 mm & ID 150 mm OD 200 mm |

| Winding coil dia. | max. 550 mm Winding coil weight |

| Winding tension | 4 – 63 kg Line is running from left to right! |

Main parts of the slitter Payoff reel 1 lot Guide roll 1 lot Cutter 1 set Winder (including expansion shaft) 1 lot Air system 1 lot Hydraulic system 1 lot Electric control system 1 lot Small hoist 1 lot Clean booth 1 lot | |

| 3. Degreasing line Mfc. | World Co. Built |

| Copper foil width | 700 mm Foil thickness |

| This line is for rolled copper foil degreasing line from pay off and winding coil | |

| Foil tension | under 45 kg/mm2 (450 N/mm2) |

| Pay off reel spool size | I.D. 290 mm * O.D.330 mm |

| Pay off reel spool width | 900 mm Pay off reel coil diameter |

| Payoff reel coil weight | max. 1500 kg Pay off reel tension |

| Winding spool | I.D. 290 mm * O.D. 330 mm Winding coil dia. |

| Winding coil weight | max 1500 kg Degreasing speed |

| Winding tension | 10-100 kg Power |

| Air | min. 0.4 Mpa (line side) Saturated steam |

| 4. Rolled copper foil surface roughness treatment line | |

| Mfc. | Kawasaki(Japan) Built |

| Width Max. | 700 mm Foil thickness |

| Specification | |

| Coil | Rolled copper foils Foil tension |

| Foil thickness | 10-50 µm Coil width |

| Pay off reel spool size | I.D. 290 mm * O.D.330 mm |

| Pay off reel spool width | 900 mm Pay off reel coil diameter |

| Payoff reel coil weight | max. 1500kg Pay off reel tension |

| Winding spool | I.D. 290 mm * O.D. 330 mm |

| Winding coil diameter | max 650 mm Winding coil weight |

| Surface treatment speed | 15 m/min. Winding tension |

| Power | AC 220 V 60 Hz, 3 ph Air |

| Saturated steam | min. 0.5 Mpa (line side) Cooling water |

| Clean water | 0.15 Mpa Pure water |

| Hydraulic power | Max. 7 Mpa Line direction |

| Line composition | |

| Pay off reel (coil car) | 1 lot Front line |

| Pickled surface chamber | 1 lot No.1 Rinse chamber |

| No.1 surface treatment chamber | 1 lot No.2 Rinse chamber |

| No.2 surface treatment chamber | 1 lot No.3 Rinse chamber |

| No.3 surface treatment chamber | 1 lot No.4 Rinse chamber |

| No.4 surface treatment chamber | 1 lot No.5 Rinse chamber |

| Rust inhibiting system | 1 lot No. 1 dry chamber |

| Chemical conversion treatment system | 1lot No. 2 dry chamber |

| Drawing and manuals |