Ref. No.:FOILRMPLANT180601

YEAR:1993-2012

Brand:MARUDHAR, SAMBHAV

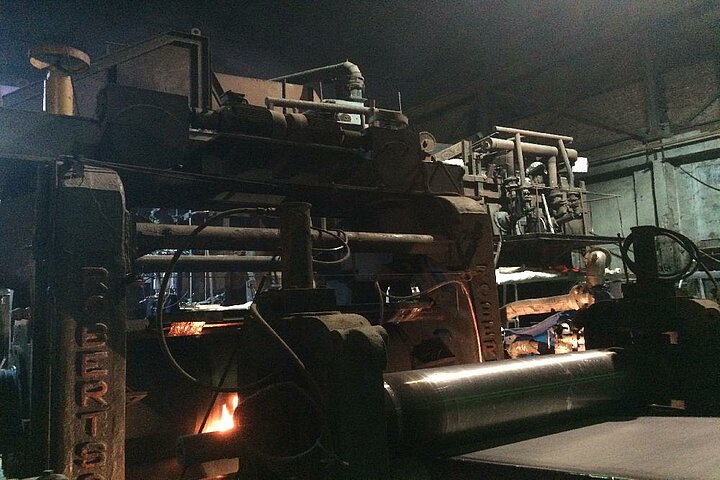

Qty:1 Second-hand aluminium foil rolling mill plant

| Description | FOIL ROLLING MILL PLANT - 1000 MM - THICKN. 8 MICRONS |

| Ref. No. | FOILRMPLANT180601 |

| Year | 1993-2012 |

| Brand | MARUDHAR, SAMBHAV |

| Qty. 1 Second-hand aluminium foil rolling mill plant | |

| Mfc. | Marudhar, Sambhav Built |

| Foil width | 1000 mm Entry thickness |

| Consist of | Melting furnace 22 MT Holding furnace 15 MT Strip caster |

| Roughing rolling mill Intermediate foil mill Finishing foil mill | |

| Heavy slitter Strip slitter Foil separator Qty. 2 Foil slitters | |

| Annealing furnace | |

| Specification | |

| Recycling aluminium melting furnace Mfc. | Sambhav Machinery |

| Bath Capacity | 22 MT Melt output capacity |

| Energy source | furnace oil fired Working Temp. |

| Material of construction | state of the art fabrication of alloyed steel plates with appropriately applied surface protections |

| Refractory lining | comprising of specially engineered high alumina bricks, insulation bricks, taper arc bricks, arc blocks, burner blocks, taping hole blocks, cast table insulation, thermal paper, ceramic board |

| Charge door dim. | 1000 x 1000 mm Carging car |

| Recycling aluminium holding furnace Mfc. | Sambhav Machinery |

| Bath capacity | 15 MT Fluxed & alloyed melt output capacity |

| Energy source | furnace oil fired Working Temp. |

| Material of construction | state of the art fabrication of alloyed steel plates with |

| appropriately applied surface protections | |

| Refractory lining | comprising of specially engineered high alumina bricks, insulation bricks, taper arc bricks, arc blocks, burner blocks, taping hole blocks, castable insulation, thermal paper, ceramic board |

| Aluminium alloys continuous strip caster Mfc. | Sambhav Machinery |

| Strip width | 1100 mm Monthly cast capacity |

| Fluxed & alloyed melt input capacity | 0.6 to 0.8 MT per hour |

| Energy source of rolls heating torch | gas fired |

| Cooling medium of rolls | water through internal grooves |

| Tip type | closed tip, open tip |

| Special feature | extremely advantageous features such as multiple width increment during running production and 15 days continuous production stretch possible due to specialized open tip technology |

| Pinch rolls lifting | push from entering strip head |

| Coiler rolls speed | completely synchronized |

| Material of construction | state of the art assembly of alloyed steel parts with appropriately applied surface protections |

| Aluminium alloys cold rolling mill Mfc. | Sambhav Machinery |

| Max. Strip width | 1050 mm Monthly rolling capacity |

| Entry thickness | 8 mm Exit thickness |

| Supplementary features | dedicated cooling and filtration systems |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminium alloys intermediate foil mill Mfc. | Sambhav Machinery |

| Monthly rolling capacity | 450 MT Max. rolling width |

| Entry thickness | 0.6 mm Exit |

| Main motor | 235 kW Un- & rewinder motors |

| Supplementary features | dedicated cooling and filtration systems |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminium alloys foil finishing mill Mfc. | Sambhav Machinery |

| Monthly rolling capacity | 200 MT @ 2 × 0.009 mm | 400 MT @ 0.02 mm |

| Max. rolling width | 1000 mm Entry thickness |

| Exit thickness | up to 2 × 0.009 mm (packed rolling) |

| Main motor | 290 kW, 500 RPM Un- & rewinder motors |

| Supplementary features | dedicated cooling and filtration systems, precise closed loop |

| guage thickness control system | |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminium alloys hot rolling sheet slitter Mfc. | Sambhav Machinery |

| Monthly slitting capacity | 450 MT Max. width |

| Max. thickness range | 2 - 8 mm Winder motor |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminium alloys cold rolling slitter Mfc. | Sambhav Machinery |

| Monthly slitting capacity | 450 MT Max. width |

| Thickness range | 0.1 mm to 0.9 mm |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminium alloys foil converting machines Two Slitters | |

| Mfc. | Sambhav Machinery Monthly slitting capacity |

| Max. width | 1000 mm Thickness range |

| Slitter’s slitting width | multiple Slit widths |

| Material of construction | state of the art assembly of alloyed steel parts with |

| appropriately applied surface protections | |

| Aluminum alloys foil converting machines Separator | |

| Mfc. | Sambhav Machinery Separator width |

| Thickness range | 0.05x2 – 0.009x2 mm |

| Aluminium annealing furnace Mfc. | Sambhav Machinery Coil dia. |

| Coil width | 1500 mm Power |

| Please advise if further information is requested. |