Ref. No.:ALUSTRIPPLANT210101

YEAR:1984 - 2015

Brand:FATA HUNTER, FRÖHLING, DE WINTER, THERMCON, SIEMENS

Qty:1 Second-hand Aluminium Strip Production plant

Built:1984, 1999, 2000, 2002, 2014, 2015

| Description | CAN STOCK STRIP PRODUCTION LINE - 220 MM - 0.15-1.0 MM |

| Ref. No. | ALUSTRIPPLANT210101 |

| Year | 1984 - 2015 |

| Brand | FATA HUNTER, FRÖHLING, DE WINTER, THERMCON, SIEMENS |

Qty. 1 Second-hand aluminium strip production plant | |

| Entry Material | Aluminium Scrap – HD666, AA5050, 2.5-3.0% Mg |

| Final product | Aluminium strip (can stock) Width |

| Mfc. | De Winter, Thermcon, Fata Hunter, Fröhling, Nederman, Burghardt & Schmidt, Siemens |

| Built | 1984, 1999, 2000, 2002, 2014, 2015 |

| Scope of supply | Melting Furnace Tilting Casting Furnace Block Caster |

5 Stand Hot Rolling Mill 6 Stand Cold Rolling Mill Hot Gas Filter Slitter | |

Welding Machine Treatment Furnace Quenching Unit Shear | |

| 1 Qty. 1 Melting Furnace Mfc. | De Winter Built |

| Type | 2 Chambers furnace Capacity |

Pyrotec mixing and overflow/transfer pump J50-SM 40” bowl | |

Natural gas 7560 kcal/Nm³ 280 mbar BTS regenerative system | |

| Main burner | 4.5 MW each 511 Nm³/h Secondary Burner 0.6 MW |

| Control Mfc. | Siemens Type |

| Scada WIN CC | |

| Utilities 400 V, 3 ph., 50 Hz Air pressure | 5 bar |

Dimensions 14.6 x 18 x 8.0 m (7.3 m above floor level) | |

Shipping dimensions 10.5 x 10.7 x 4.5 m – largest part | |

| Weight | approx. 521 t – Total Main part |

| 2 Qty. 1 Tilting Casting Furnace Mfc. | Thermcon Built |

| Natural gas 7560 kcal/Nm³ Main burner | 1.9 MW Sec. Burner 0.6 MW |

| Control Mfc. | Siemens Type |

| Utilities 400 V, 3 ph., 50 Hz Air pressure | 5 bar |

Dimensions 9 x 8 x 9 m (7 m above floor level) | |

| Shipping | 8.3 x 6.6 x 4.3 m (max. part) Weight |

| 3 Qty. 1 Continuous Block Caster Mfc. | Fata Hunter Built |

| Block size | 350-480 x 26 mm – W x T Flat bed / solidify length |

| Tilt angle | 0 – 15° Speed |

| Inflow | Laser controlled down spout Water coolant 0 – 30°C |

| Control Mfc. | Siemens Type |

| Utilities 400 V, 3 ph., 50 Hz Air pressure | 5 bar |

| Dimensions 7 x 8 x 6 m Total weight | 35 T Main part |

| 4 Qty. 1 Continuous 5 Stand Hot Rolling Mill Mfc. | Fata Hunter Built |

| 2 Rewinders Strip width | 480 mm Thickness |

| Speed | 65 m/min Coil ID 600 mm OD 1250 – 2000 mm |

Work roll Dia. 470 x 550 mm AC stands motors 250 kW, 12 puls converter | |

| Coolant Lubrication emulsion Mfc. | Schneider 2500 L/m – 150 m³/h |

| Control Mfc. | Siemens Type |

Safety PLC - Pilz PSS1 Interstand tension control ABB | |

Thiockness control ABB (hydr., output measuring) | |

Utilities 400 V, 2x3 ph., 50 Hz (dedicated transformer) | |

| Air pressure | 5 bar Water cooling |

Dimensions 36 x 16 x 7 m 4 m above floor level | |

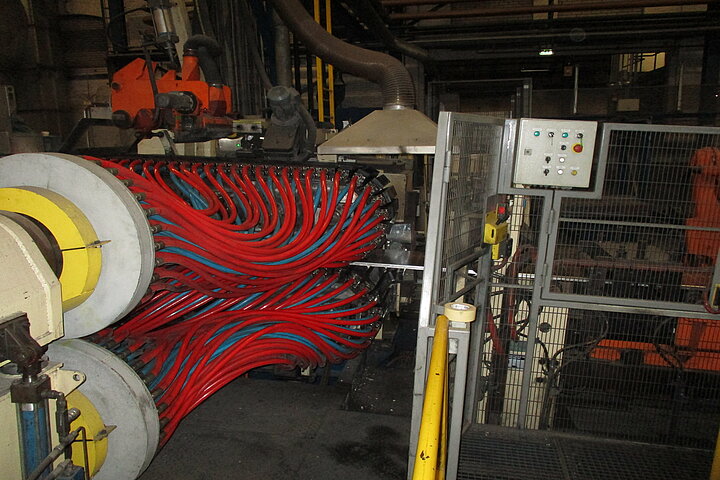

| 5 Qty. 1 Continuous 6 Stand Cold Rolling Mill Mfc. | Fröhling Built |

| Type | 4-Hi Strip width |

| Speed | 500 m/min. Coil ID 400 mm Entry OD 2000 mm Exit OD 1200 mm |

Back-up roll dia. 270 x 290 mm Work roll dia. 130 x 300 mm | |

Motors DC – ABB converters (revamped in 2008) 100 kW drive – work rolls | |

Control PLC system (2008) Siemens S7-400 Reliance Automax (weld) | |

ABB – AC31 (control stands & flatness) Safety PLS – Pilz PSS1 | |

SCADA – Simplicity Interstand tension control | |

| Flatness control | Stand 6 |

| Thickness control | hydraulic, each stand, output measuring – Vollmer |

Utilities 380 V, 3 ph., 50 Hz Air pressure 5 bar Water cooling | |

Dimensions 55 x 10 x 4/19 m | |

| 6 Qty. 1 Hot Gas Filter Mfc. | Nederman Built |

| Capacity Flow | 45000 Nm³/h Temp. |

| Main fan Mfc. | Danfoss Power |

Control Siemens PLC S7-1500 Panel Simatic TP700 Touchpanel | |

Utilities 400 V, 3 ph., 50 Hz Air pressure 5 bar | |

Dimensions 12 x 8 x 8 m | |

| 7 Qty. 1 Slitting line Mfc. | Burghardt & Schmidt Built |

Noise reducing cabine Scrap exhaust system | |

| Strip width | 480 mm Thickness |

Coil Entry ID 600 mm – OD 2000 mm Exit ID 400 & 600 mm – OD 2000 mm | |

| Coil weight | 3650 mm |

| Slitter knife Outer dia. | 250 mm Inner dia. |

Motors AC – Control Technics | |

| 8 Qty. 1 Strip welding machine (Cold mill) Mfc. | A.I. Welders Built |

| Revamped in 2002 Speed | 75 – 600 m/min. |

| Strip width | max. 233 mm Thickness |

| Complete cycle | 45 sec. Welding |

| Welding transformer | 250 kVA Control PLC – Reliance – Automax 7010 |

| Voltage | 380 V, 3 ph., 50 Hz Pressure hydr. |

| Air pressure | 6 bar |

| Dimensions | 3.5 x 4.5 x 1.8 m |

| 9 Qty. 1 Induction Treatment Furnace (Cold mill) Mfc. | Otto Junker Built |

| Strip width | 220 mm Thicknes |

| Speed | 8 – 60 m/min. Temperature |

PLC system 2002 Thyristor control – O.Junker – 2003 | |

| Heat treatment length | 16 m Thickness control Mfc. Vollmer |

| Induction heating oven Power | 1.0 MW Length |

| Holding oven Length | 3.0 m/zone |

| Power Zone 1 | 8.2 kW Zone 2 |

| Temperature control Induction oven | 3T P3000 Profile |

| Holding oven | Thermocouple Exit – Zone 5 |

| Position control steering rolls & induction | EMG |

| Voltage | 380 V, 3 ph., 50 Hz Cooling water |

| Total length | 19.5 m |

| 10 Qty.1 Quenching unit (Cold mill) Mfc. | Otto Jumker Built |

| Flow | 95 m³/h Temperature |

| Flat bed gravity filter Surface | 0.9 x 3.8 m Size |

Qty. 2 Rolls Dia. 60 cmm First tilting Second fixed | |

Voltage 380 V, 3 ph., 50 Hz Cooling water 25 °C Air pressure 6 bar | |

| Dimensions | 3.5 x 4.5 x 1.8 m |

| 11 Qty. 1 Rotary shear (Cold mill) Mfc. | HDE Built |

| Strip width | 220 mm Thickness |

| Speed | 75 – 600 m/min. Motor power |

| PLC system Mfc. | Reliance Automax 7010 Drive ABB |

| Voltage | 380 V, 3 ph., 50 Hz Air pressure |

| Dimensions | 0.6 x 0.9 x 2.0 m |