Ref. No.:TUBEWELDL190701

YEAR:1998

Brand:Guida Impianti, Otomills, Elmat

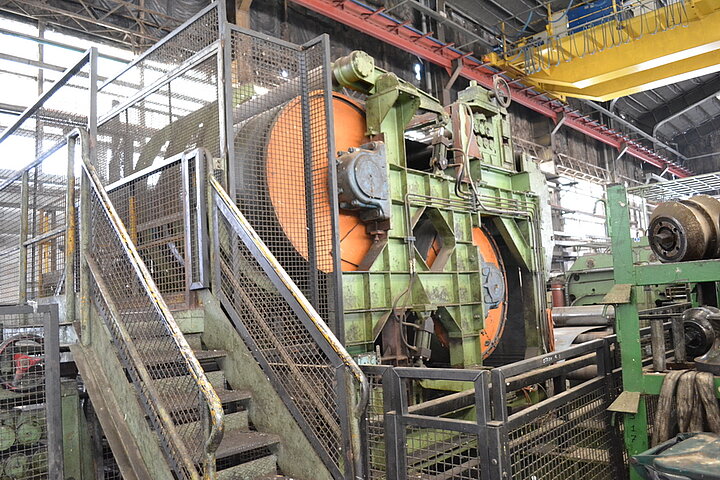

Qty:1 Second-hand tube welding line – ERW-type - 8'' - 16''

Qty. 1 Second-hand ERW tube welding production line

Mfc.: Guida Impianti, Otomills, Elmat, Built: 1998, Modernised: 2006-2010, Stopped: 2010

Welding technology: ERW

Material: Pickled and black carbon steel strips S235 – S355

Strip Width: 690 - 1300 mmm, Thickness: 3 - 8 mm, Coil Weight: 27 tons

Internal diameter: min 508, max 810 mm, External diameter: 900 - 2100 mm

Tensile strength: max 510 N/mm2, Yield strength: max 355 N/mm2

Characteristics of output material:

Diameters: 8” – 16”

Round tubes: Ø 219-235-244.6-253.5-273-285-305-317-323.9-355.6-381-406.4-413 mm

Square tubes: 200x200-220x220-250x250-260x260-300x300-325x325 mm

Rectangular tubes: 200x150-250x100-220x140-250x150-300x100-260x140-300x150

Length: 4,500-12,000 mm

Finishing, Internal decreasing, External decreasing, Bevel of ends, Blowing system, No destructive controls, Elotest in the welding area

Tolerances on length: +/- 5 mm

Entry section speed: 120 m/1’, Welding speed: max 35 m/1’

SCOPE OF SUPPLY:

ENTRY SECTION

Saddle coil storage, Coil car, Uncoiler with opposing mandrels, Motorized snubber roll for press coil, Coil opener table, Pinch roll + flattener Steering unit, Facing shear with scrap container, MIG welder with shear included Deflector roll

PROCESS SECTION

Looper with loop car pulled by winch pull and 14 arms of support strip Two rolls bridle with snubber roll

Steering unit with vertical rolls

FORMING SECTION

It consists of: n° 2 brake down, n° 6 steps of forming intercalated, of n° 6 vertical formers, n° 3 steps of finishing

WELDING SECTION

Welding head with four rolls, Welding plant ELESTAR with contacts 450 kW - 400 kHz

COOLING SECTION

On free air with space for inductors of normalization of weld bead Supports of tube

Spray nozzle for cooling with emulsion

CALIBRATION SECTION Cost

n° 3 motorized cages of calibration with four quick change rolls and locking systems n° 2 turkish heads and straightening system of bars

Elotest for control of welding area, with off line calibration system

Ecomag NDT welding Check

CUT OFF SECTION

Flying cutter with quick saw, clamps and tube support system, with soundproof cabin

DISCHARGE SECTION

Motorized conveyor, Waste basket of scraps, Feeding device for tube packs to header

FINISHING SECTION

Plant of bevel for tubes according API norm, Blowing system for removal of internal welding

PACKAGING SECTION

Rollers way of transfer, with amortized wing, dual discharged section and packaging of packs

AUXILIARIES

Hydraulic system, Pneumatic system, Equipment for assembly and disassembly of rolls

ELECTRIC SECTION

Electric equipment, control panels and software, electric cables

TOOLING

Tooling for round, square and rectangular tubes

VERY EXTENSIVE LIST OF SPARE PARTS (CAN BE SENT UPON REQUEST)