Ref. No.:STRIPCASTINGL200501

YEAR:1992 - 2000

Brand:EMA, MARX, AIR BLUE, DEMAG, BUCHHOLZ, SMS

Qty:1 Second-hand strip casting production line

Built:1992, 1995, 1997, 1999, 2000 Income material

| Description | STRIP CASTING LINE - 300 MM (W) - 10 MM (TH) - POSSIBLE BELOW |

| Ref. No. | STRIPCASTINGL200501 |

| Year | 1992 - 2000 |

| Brand | EMA, MARX, AIR BLUE, DEMAG, BUCHHOLZ, SMS |

We have pleasure to provide you with an offer about second-hand strip casting production line | |

that has been used for development for special strip production and now due that the project | |

| has been finished it is immediately for sale. | |

It can be also used for any developement and reseach work if there is any request to produce | |

| special strip material. | |

The strip caster described here has been used for research and development since 1992 of | |

465 tests carried out on a 500 kg or 1 t scale. Mostly, steel was poured, with the focus in recent years on new, high-alloy steels. | |

In addition, copper, brass and silicon were successfully cast. | |

The casting process is computer controlled / - regulated and fully automatic. Oven, casting machine and the subsequent cooling section are under inert and partially reactive gas atmosphere operated. It is possible to inline hot rolling and subsequent water spray cooling. | |

The cast strip can run out as a plate on a roller conveyor or be wound up as a coil. | |

The entire system and all of its components are ready for use. All components are on the floor. | |

A very desirable alternative would be to continue operating the existing pilot plant as part of new research and development projects in the field of iron ore non-ferrous metallurgy. | |

| Qty. 1 Second-hand strip casting production line | |

| Mfc. | EMA-Indutec, Marx, Air Blue, Güntner, Demag, G. Buchholz |

| Built | 1992, 1995, 1997, 1999, 2000 Income material |

| Strip width | 300 mm Thickness |

| Plate length | 16 m can be extended! Coil weight |

| Scope of supply | Induction crucible furnace 20 kV Transfomer Cooling unit |

| Casting machine Duo Mill Stand Coiler Run-out table | |

| Quenching Compressor | |

| Spezification | |

| Induction Crucible Furnace | |

| Converter Mfc. | EMA – Indutec Type |

| Type | Medium frequency thyristor converter Built |

| Operation hours | ≤ 6000 h Nominal active power on the output side |

| Nominal voltage on the output side | 700 V Nominal frequency on the output side |

| Electrical supply | 3 x 510 V / 679 A / 50 Hz (Power) 3 x 380 V / 25 A / 50 Hz (Control) |

The lines for electricity and coolant between the converter and the furnace coil are flexible to allow the furnace body to be lifted and moved. | |

The converter includes a transformer for connection to the medium-voltage network | |

| Nominal voltage on the input side | 20 kV Nominal voltage on the output side |

| Nominal apparent power | 600 kVA Type |

| Furnace body | |

| Coil Mfc. | Marx Built |

| Dimensions | ID 810 mm Height |

Suitable for operation with small quantities of feed materials / melt. | |

The furnace can be operated stationary in a tilting frame or mobile on the indoor crane | |

| Stationary operation | Conventional pouring over the snout |

Switched on oven hanging on the crane (mobile operation) | |

Attaching the furnace body to the crane using a special traverse with integrated weight | |

measurement to determine the melt mass during the casting process. | |

Maximum furnace travel currently approx. 6 m (relatively easy to expand by exchanging the | |

| flexible lines) | |

| Moving the furnace body under electrical load possible | |

Casting by means of floor tapping with stopper mechanism (manual or automatic control) | |

Additional plate slider for emergency closing of the floor cut if the plug fails | |

Including replacement plug (approx. 40 pieces made of alumina graphite and 2 pieces made of | |

| AM spinel) | |

| Crucible | |

| Nominal capacity | 1.0 to 1.3 t Fe |

| Ready crucible | Own form available at manufacturer MiTec Middeldorf; |

| incl. 2 new crucibles | |

Alternatively self-made by stamping (sintering template available) | |

| Safety devices against melting breakthrough | earth fault monitoring and temperature measurement in back ramming |

| Cover | |

Roughly gas-tight; Fumigation of the melt with argon, for example; thereby generating u. a. high-alloy steels with controlled and low erosion of alloying elements and low absorption of nitrogen etc. possible (extensive experience and chemical analyzes available) | |

Various flaps and bushings (for continuous temperature measurement, sampling, alloying, stopper rods, flushing lances, etc.) | |

| Cooling unit for the Converter | |

| Mfc. | Air Blue Type |

| Design | Axial fan, scroll compressor, closed coolant circuit |

| Coolant | Glycol with low electrical conductivity |

| Cooling unit for the furnace coil | |

| Mfc. | Güntner Type |

| Type | Axial fan, closed coolant circuit Coolant |

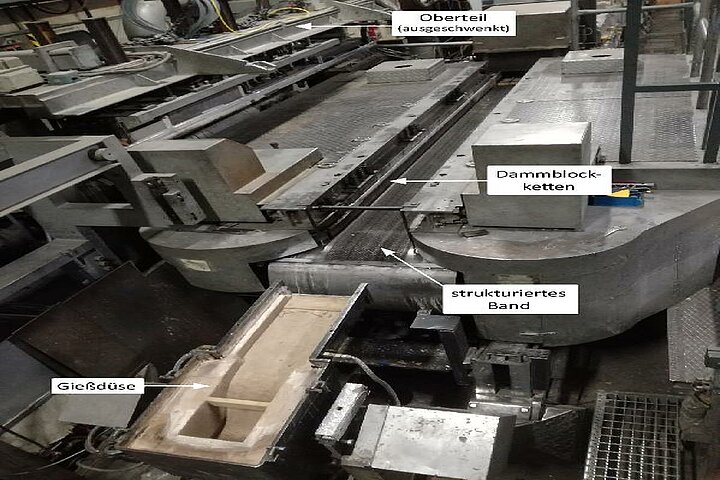

| Casting machine | |

| Mfc. | Gustav Buchholz Modifications by SMS Built |

| Casting strip width | 300 mm |

| Casting thickness | adjustable in the range of approx. 10 to 20 mm, usually approx. 15 mm |

Pouring on all-round structured steel strip, water-cooled from below (machines for producing such strips available) | |

Side limitation through all-round, water-cooled dam block chains | |

Influencing the melt flow by electromagnetic stirrers and argon rake | |

Inertization of the entire casting machine and cooling section | |

| Swiveling, heatable pouring nozzle | |

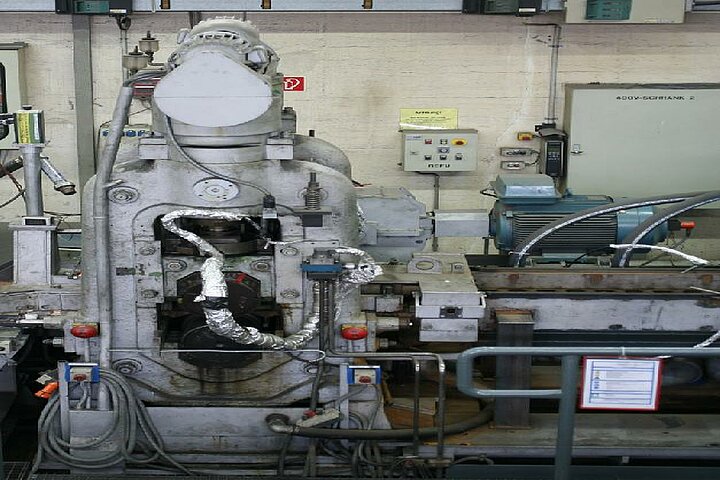

| Mill stand | |

| Mfc. | DEMAG Built |

| Main motor power | 60 kW incl. gear box Qty. 6 Spare rolls |

| Roll dia. | 295 mm Barrel length |

| 4. Other plant components | |

If necessary, detailed descriptions of the other parts of the system are provided of | |

| - Coiler | |

- Cooling water supply for the casting machine and other system components (tank, various pumps, mixing system etc.) | |

- Optional spray cooling / quenching immediately after the roll stand | |

- Special machines for in-house production of the circulating belt for the casting machine (embossing with special patterns, welding) | |

- Resistance-heated small furnace for preheating the pipe socket | |

| - Driver unit immediately after the rolling stand | |

- Three pyrometers for measuring the cast strip temperature | |

| - Gas supply | |

| - Compressed air supply |