Ref. No.:SKINPASSMILL221101

YEAR:2004

Brand:ANDRITZ

Qty:1 Second-hand skin pass mill

Qty. 1 Second-hand skin pass mill

Mfc.: Andritz, Type: SK03, Built: installed in 2004 on the basis of an Andritz stand from 1989

Products: Cold rolled, hot rolled pickled, galvanized, zinc plated oil-free

Max. Speed: 300 m/min., Thickness Entry: 3.05 mm, Exit: 0.45 mm

Strip width: 700 – 1,505 mm, Max width on annealed strip: 1,605 mm

Max Section (Width x Thickness): 4,500 mm², Max Weight: 30 T

Working rolls dia.: 380/425 mm

De-Coil Inner Dia.: without extension: 610 mm, with extension: 740 – 780 mm

Max De-Coil Outside Dia.: 1,900 mm, Min. Outside Dia.: 1,000 mm

Coil ID: 610 mm, Coil OD: 1,000 – 1,880 mm, Coil weight: 30 T

Oiling Capacities: 1.0 to 3.0 Gr / m² / 2 Sides, Elongation: 0.2 to 2.0%

Electrical engineering by Alsthom (GE Power conversion):

- The motors are DC motors.

- The installed power is around 2,000 KVA, 410 V, 3 hp

1. FEEDING AND SUPPLY STATION

The assembly is perpendicular to the longitudinal axis of the skin pass. It's made of:

a) TWO FEEDING STATIONS:

Mechanically welded frames on which wooden skids are fixed for protection.

Recovered stations.

b) AN UNWINDING STATION:

Mechanically welded frame supporting motorized steel rollers of dia. 280 mm.

Its purpose: to ensure the manual stripping and the introduction into the preparation station of the start of the coil, non-compliant in thickness.

c) A DROP STATION: recovered material

Made of :

- 1 engagement spade

- 1 set of trainer rollers

- 1 hydraulic shear capable of a max. thickness of 5 mm Material entirely recovered, in good condition

d) All of the above positions are served by an UNDERGROUND HYDRAULIC MOTOR AUTO TRUCK comprising:

- 1 group for elevation: parallelogram system - stroke 750 mm

- 1 translation - stroke 11 m: hydraulic system or electric motorization but 2 speeds

New equipment defined by specifications

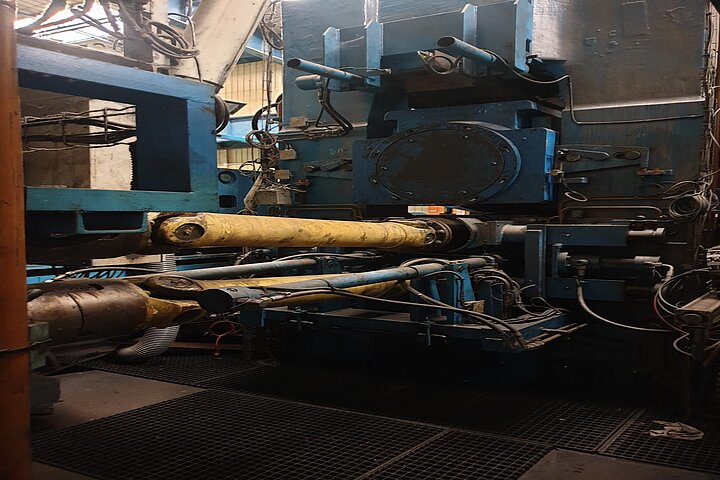

2. SKIN PASS MILL

a) AN UNWINDER:

Chuck diameter 610 mm, suitable with a nose

Chuck, reducer, brake, motor assembly, mounted on a single frame with positioning pallet

Strip running speed: 300 m/min, Power: 400 kW

Set recovered and adapted for the new speed and the weight of 30 T

b) A CHUCK NOSE:

Mechanically welded, retractable

Able to support the additional weight and leaving free the passage of a coil with an external diameter of 1,900 mm

The assembly is fully hydraulic new equipment

e) S-ROLL:

Mechanically welded, ensuring the drive of the belt head towards the S-block Material fully recovered

d) ACCESSORIES:

A bracket is provided to collect butts and distribute them in a skip provided for this purpose (adapted bracket)

e) A RECOVERED ENTRY SET:

Including a fixed table on which is articulated a scissor facilitating the introduction.

It is modified to allow the maximum coil dia. 1,900 mm

f) AN S-BLOCK:

Used in motorized restraint - overall installed power: 350 KW It is composed of:

- 2 main rollers diameter 700 mm in steel

- 2 coated rollers diameter 250 mm motorized by hydraulic motors and reducer

- mobile deflectors fitted with bearings allowing the introduction of the strip up to the dia. 500 mm deflector roller