Ref. No.:PETFILLER200201

YEAR:2006

Brand:SIPA, UNIFIL AG, HORMES, SIEMENS ETC.

Qty:1 Second-hand complete PET hot fillinge line

Capacity:26.000 bph of 0.5 L

Built:2006 Capacity

| Description | PET FILLING LINE -JUICE-NECTARS-DRINKS - 0.5 L & 1.0 L - 17500 BPH |

| Ref. No. | PETFILLER200201 |

| Year | 2006 |

| Brand | SIPA, UNIFIL AG, HORMES, SIEMENS ETC. |

| Qty. 1 Second-hand complete PET hot fillinge line | |

| Mfc. | SIPA, Unifil AG, Lanfranchi, Hormes, Miho, ACM, SMB, General Dynamics SRL, Finpac, |

Linx, Verpackungstechnik GmbH, Stretcher AG, CFT SpA, etc. | |

Most of PLC are SPS Siemens Simatic S7, Blum, Kisters, Kettner “Pressant Universal” | |

| Built | 2006 Capacity |

| Product | Juices, nectars and still drinks (with option for CSD, which never used). |

Bx 0-14, pH 2.8-4.2, Viscosity 1-12 cp, cells - up 10% | |

| Bottle material | Plastic (PET), bottle weight |

| Bottle size | 0.5 L & 1.0 L, Square bottles, cross section 50 / 95 mm, height 110 /330 mm, |

| neck finish - 38 mm | |

| Cap | 38 mm (1690) Bericap Type SK38/16 S DS HF |

| Labels | Sleeve label |

| Packing | Cases 4x6 for 0.5 L Cases of 3x4 for 1.0 L Flat carton tray |

| Palletising | option of carton sheet between layers; stretch wrapping of pallet. 44 pallets/h |

| PET-line includes | |

1 Single-stage PET injection blow molding machine Sipa ECS FX 12/40 | |

| 2 Conveyor blown bottles | |

| 3 Storage SILO V=300 m³. Storage capacity | 200.000 bottles of 0.5 L |

| 4 Steril air-drying system for Silo | |

| 5 Bottle unscrambler Lanfrachi. Capacity | 30.000 bph a 0,5l |

| 6 Air conveyors EOLO 43 m | |

7 Counter pressure filling and closing machine blocked with a rinser | |

| Hollstein & Kappert VVF 108 | |

8 Cap sterilisation with steam tunnel and peroxyd bath. | |

| Capacity | 26.000 bph of 0.5 L |

9 Cap feeding system for conveying of screw caps Hormes | |

10 180° turning conveyor to sterilize the caps after filling | |

11 Fill height and cap control MIHO NEWTON-EC 2001 | |

12 Processing (mixing / dearetion / heating) and pasteurizing unit | |

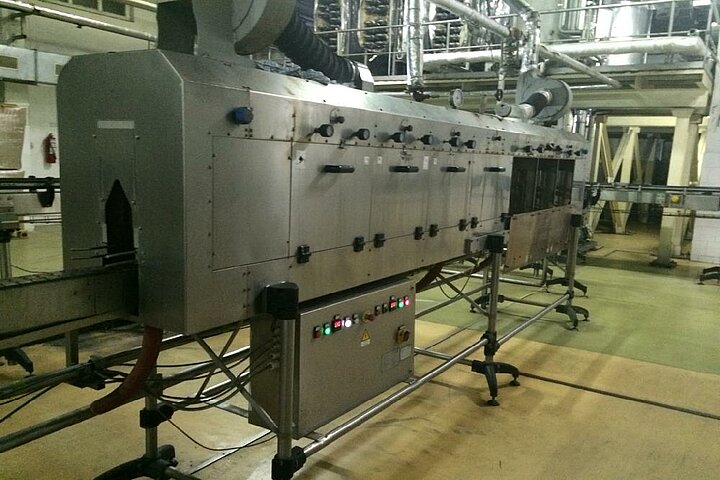

13 Combinated cooling/warmer tunnel. Niko/SMB 04.1.1.156. | |

| Capacity | 30.000 bph of 0.5 L |

| 14 Conveyor system filled bottles | |

15 Bottle drying station (2 blowers, one at the discharge of the cooling tunnel) | |

16 Labeling machine for applying sleeve labels FINPAC SHM HS | |

| 17 Date coder | inkjet printer Linx4900Ink Jet |

18 Tray packer, foil wrapping and shrinking unit KISTERS ZVT / TSP 030S. | |

| Capacity | up to 40 cycles/min. |

| 20 Conveyor system for packaging 38 m | |

| 21 Fully automatic palletizing unit KETTNER | |

| 22 Fully automatic empty-pallet magazine KETTNER. Capacity | max. 15 pallets |

| 23 Вriven pallet – conveyor segment KETTNER | |

| 24 Pallet stretcher Swiss Stretcher 9000 |