Paper Industry

BABY DIAPERS LINE - MINI-MIDI-MAXI-JUNIOR - PANNOLINI 50 IMD

Ref. No.:DIAPERL190801

YEAR:2015

Brand:MAQMANTAS

Qty:1 Second-hand baby diaper production line

Specification

| Description | BABY DIAPERS LINE - MINI-MIDI-MAXI-JUNIOR - PANNOLINI 50 IMD |

| Ref. No. | DIAPERL190801 |

| Year | 2015 |

| Brand | MAQMANTAS |

| Qty. 1 Second-hand baby diaper production line | |

| Mfc. | Maqmantas Type |

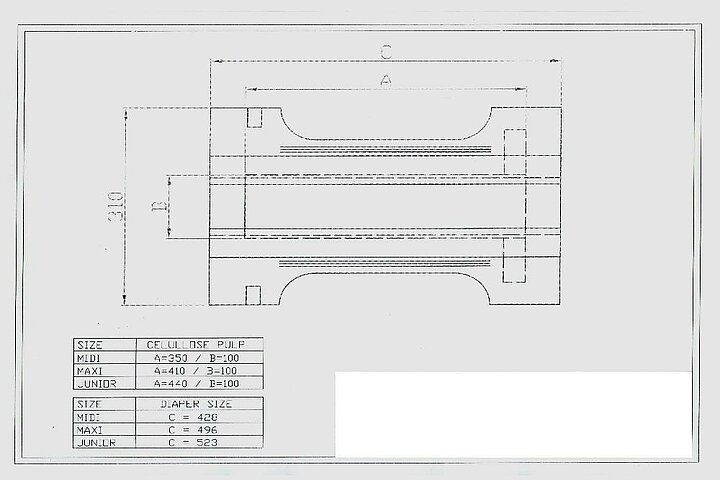

| Size of diapers | Mini, Midi, Maxi, Junior Nominal Production |

| Dimensions | 4800 x 950 x 2050 (L x W x H) mm (without exhauster) |

| Room dimensions | 21 x 5.3 x 3.1 m – L x W x H |

| Voltage | 3 ~ 220 V, 3 ph., 60Hz, 100 A Power |

| Theoretical Weight | 1500 kg Screw compressor |

| The machine can be demonstrated in running conditions. | |

| Specification | |

| Production Line | |

| Adjustable brackets for roll fabric with mechanical brake. | |

| Cylindrical rollers and tensioners for closing the diaper | |

| Liquid suction insert for manual feeding | |

| Positioning sensor and pneumatic stepping device | |

| Aluminum profile support. | |

| Hot-Melt Adhesive Melt Container | |

| 1. Container with an adhesive melting capacity of 18 kg. | |

| 2. 2 | 1 electric motor with frequency converter 1 |

| 3. Electric panel with 9 temperature controllers. | |

| 4. With distribution filter and 4 outputs. | |

| 5. 04 pcs 2.00 m long thermoelectric hoses. | |

| 6. Block 01 with 10 modular adhesive, 300 mm polyethylene. | |

7. 01 Double block for non-woven and rubber weave with 5 and 2 module adhesives | |

| 8. 01 Double Block with 2 and 2 Modular Adhesives | |

| 9. 01 Block with 2 Module Adhesive for Rubber Wire. | |

| 10. 23 nozzles with adhesive. | |

| 11. Magnetic Valves 24 Vdc. | |

| 12. Sockets. | |

| 13. Hoses and Pneumatic Connections. | |

| Rubber-coil winding dispenser | |

| - Coordinated dosing of 8 coils of rubber at same time | |

| - Coiled roller rollers with drive inverter and gear motor. | |

| Control cabinet | |

| - Speed control electronics - thermal relays | |

| - drive tuners - control knobs - liquid crystal displays | |

| - start-stop-emergency stop relays. | |

| Side adhesive tape applicator | |

| - Rotary belt conveyor and automatic cutting unit | |

- Symmetrical vacuum roller belt feeder with mechanical brakes | |

| Side Adhesive Folding Applicator | |

| - Side Adhesive Latch Locking System Drive Element | |

| - Lower roller silicone rubber rollers | |

| First Velcro Applicator | |

| - Rotary belt conveyor and vacuum cutting unit | |

| - Adjustable support for tape roll. | |

| - Vacuum pump with motor | |

| Anatomical Cutter Applicator | |

| - Industrial cutting roller | |

| - 2 high-performance extraction engines | |

| - Cutting waste extraction system | |

| Liquid Leak Damper Applicator | |

| - Adjustable brackets for roll fabric with mechanical brake | |

| - Ipai cutter blade with electric motor | |

| - Tension rollers | |

| - Special material fold system | |

| - Sensor-controlled sectional hot-melt adhesive | |

| Length Folding Applicator | |

| - Nylon roller for longitudinal drive. | |

| - Adjustable material drive guide rods | |

| Cutting Applicator | |

- Adjustable sensory cutting knife and knife holder for final diaper cutting | |

The length of the diaper is changed mechanically to the size of the diaper | |

| and the number of gears. | |

| Strips and cuts are positioned by setting the nodes. | |

| Pneumatic Packer | |

| - Pneumatic foot valve | |

| - Pneumatic cylinders | |

| - Aluminum dispensing table | |

| - Industrial slicer applicator | |

- liquid absorbent material (rolls) for slicing S - M - L - XL inserts |